A Comprehensive Guide to Recognizing Litho Printing Methods

The globe of litho printing, a method stemming from the late 18th century, is a fascinating blend of history, art, development and science. Keep with us as we journey right into the captivating world of litho printing.

The Historical Advancement of Litho Printing

The historical trajectory of litho printing, a pivotal advancement in the realm of interaction, is a captivating tale of human ingenuity. The procedure progressed with the arrival of the rotary press, which substantially increased performance. Each phase of litho printing's evolution showcases humankind's ruthless pursuit of performance and high quality in aesthetic communication.

Decoding the Science Behind Litho Printing Inks

Relocating ahead in the expedition of litho printing methods, the focus currently moves to the science behind litho printing inks. The structure of these inks, their drying process, and shade mixing techniques form the backbone of this intricate art form. Recognizing these components is important to understanding the craft and achieving the preferred print results.

Structure of Litho Inks

In lithographic printing, the basic duty of litho inks can not be overemphasized. The make-up of litho inks varies relying on its purpose, however typically, they include two main parts - vehicles and pigments. Pigments, the color-providing aspects, are carefully ground particles put on hold in the automobile, a liquid that carries the pigment onto the printing surface area. The vehicle is a complex mix of solvents, oils, and materials, which influence the ink's drying out time, adhesion, and gloss. Furthermore, different additives are present to boost specific residential properties like circulation, drying, and resistance to ecological effects. Each component plays a critical part in the final print's high quality, making the specific formulation of litho inks a detailed scientific research.

Ink Drying Process

From the composition of litho inks, attention turns to the remarkable procedure of ink drying out. The drying out procedure is vital, as it impacts the last print's high quality and longevity. 2 primary methods are made use of in litho printing: oxidative drying and absorption. Oxidative drying includes the ink responding with oxygen airborne to create a hard, dry movie. This approach supplies a durable coating, however can be slower compared to absorption. Absorption, on the other hand, involves the ink leaking into the paper fibers, which is a much faster procedure but can cause much less dynamic colors. The option in between these approaches depends on elements such as print rate needs, the paper kind utilized, and the desired coating.

Color Combining Strategies

While the drying out procedure plays a key function in litho printing, the scientific research of shade mixing strategies holds equal relevance. The scientific research behind litho printing inks likewise takes right into account the openness of the ink, which influences how shades overlay and mix.

The Art and Design Elements in Litho Printing

Litho printing takes a breath life right into art and design through its distinct aspects. The process entails developing a photo on a lithographic sedimentary rock plate or steel plate with a smooth surface area. The picture is after his comment is here that printed onto a medium, typically paper, by moving the ink from home plate. What sets litho publishing apart is its ability to replicate elaborate layouts with high integrity, making the outcome virtually the same to the original art work. This is achieved through making use of various line techniques such as hatching, stippling, and cross-hatching, which enable for an array of tonal effects. Litho printing fits a range of colors, allowing artists to produce lively and vibrant prints. This mix of precision and adaptability makes litho printing a favored choice for several artists and developers.

Modern Applications of Litho Printing Techniques

Litho printing methods have actually located considerable usage in the modern-day commercial industry. Its impact and significance continue to grow with the arrival of new advancements and technologies in the area. This area will certainly explore these contemporary applications and the transformative role they play in the printing market.

Industrial Litho Printing Makes Use Of

Litho printing stays a critical part of the commercial sector. High-volume printing jobs, such as the manufacturing of books, papers, and product packaging, rely on litho printing for its capacity to supply remarkable photo top quality and price efficiency. Litho printing also offers a broad shade spectrum, remarkable to that of digital printing.

Technologies in Litho Printing

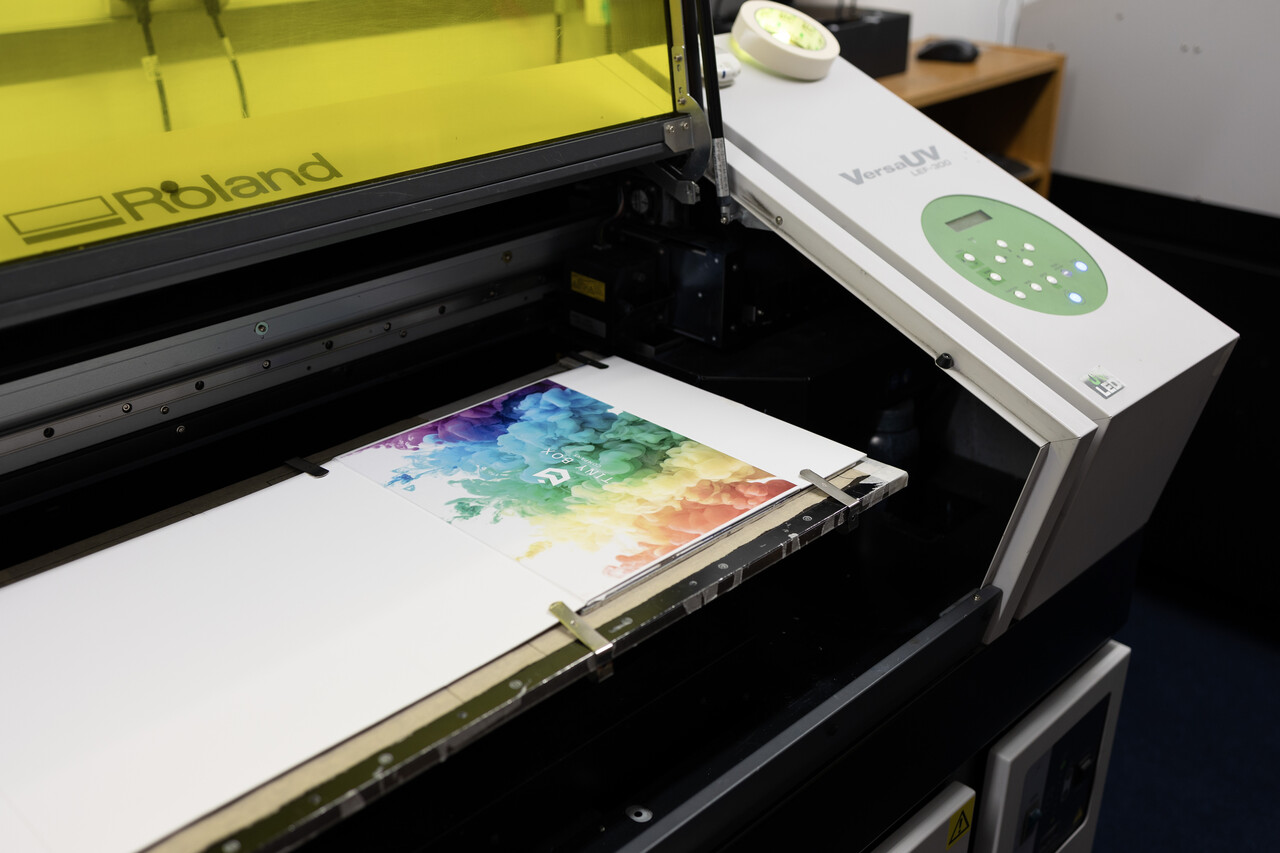

Pushing the boundaries of traditional methods, modern improvements have actually sustained a host of technologies in litho printing. One noticeable development is digital litho printing, which incorporates the virtues of electronic innovation with litho's high-quality result. These innovations highlight the long-lasting relevance of litho printing in the contemporary globe.

Exploring the Refine of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

Regardless of the precision and custom that litho printing proudly supports, it is not without its set of contemporary challenges. Digital litho printing allows for cost-efficient short runs and very easy customization, addressing the concern of variable data. Hence, while there are difficulties, the litho printing sector is proactively adjusting to fulfill them head-on, guaranteeing its significance in the future.

Conclusion

Finally, litho printing, with its rich background and clinical ins and outs, holds a considerable place in the print market. As the overview exposes, it's a synthesis of art and technology, with modern-day innovations ensuring its importance. The industry encounters difficulties that require cutting-edge services, with a focus on automation and sustainability. The future of litho printing hinges on its ability to adjust to these altering needs, verifying its enduring worth in a developing market.

Comments on “litho printing Techniques Used by Top Print Shops”